CRFS Development

CRFS-LL communication & dissemination plan

In the scope of Arganda lab, communication and dissemination activities will be done in the form of physical workshops and publication on scientific dissemination channels.

- Physical workshops: The workshops will be promoted by the CRFS-LL Coordinator (LLC) and will have the task of validating the developments incorporated into this lab with users, through demonstrations, in order to obtain feedback that will improve the integration of these IT systems in subsequent iterations. The workshops will be aimed at two audiences:

- Consumer workshop: The target groups invited to this workshop with regular consumers, either technology or food products. The objective is to obtain feedback on the general public's perception of the innovations proposed in the Arganda lab. These workshops will be held mainly at the UPM facilities.

- Expert workshop: The target groups invited to this type of workshop are professionals from one of the food system links, who are used to dealing with food production systems, traceability, waste management, packaging, labelling, among others. The objective of this type of workshop is to obtain a more detailed opinion on some specific aspect of the proposed innovations, so that they can improve day-to-day work in these food systems. An example may be presenting factory workers with a new application that manages incidents that may occur in the manufacturing process, in order to obtain recommendations to improve this application and adapt it to real food production scenarios. These workshops will be held mainly in expert’s facilities.

Information is not yet available on the number of workshops that will be held during the life of this living lab, but it depends on the number of experiments carried out, as will be seen in the next phases that will be mentioned in the Handbook.

Systems Thinking

Carry out Systems Thinking Workshops (STW) with local stakeholders

Consumer workshop: The target groups invited to this workshop with regular consumers, either technology or food products. The objective is to obtain feedback on the general public's perception of the innovations proposed in the Arganda lab. These workshops will be held mainly at the UPM facilities.

-

Consumer workshops have been carried out where systems thinking has been explained and some questions have been asked to food consumers in Madrid (Spain): 20 April 2022. A questionnaire was provided and consumers received a gift (pastry product) for answering the questionnaire. 55 responses were collected.

Expert workshop: The target groups invited to this type of workshop are professionals from one of the food system links, who are used to dealing with food production systems, traceability, waste management, packaging, labelling, among others. The objective of this type of workshop is to obtain a more detailed opinion on some specific aspect of the proposed innovations, so that they can improve day-to-day work in these food systems. An example may be presenting factory workers with a new application that manages incidents that may occur in the manufacturing process, in order to obtain recommendations to improve this application and adapt it to real food production scenarios. These workshops will be held mainly in expert’s facilities.

- One expert workshop was held the 8th of July 2021 in a processing company facility (Arganda municipality) where experts in food processing exchanged ideas of how technology can help process automation in Industry 4.0.

Figures 4, 5: Expert workshop: 10 participants

PESTLE analysis

|

Dimensions |

Drivers |

Trends |

Impacts |

|

Politics |

Regulations such as labour, minimum wage, food storage, are very present in Spain. |

Regulations make food production and processing one the most regulated businesses. |

Production systems become more complex and solutions in the field of food production become multifaceted. |

|

Economy |

The latest economic events such as the COVID crisis and geopolitical conflicts are having an impact on the price of energy and a disruption in the food supply. |

There is an increase in energy prices and it is difficult to deal with suppliers. |

There is an increase in the cost of food production, both due to the increase in the cost of raw materials and the increase in production costs. |

|

Cultural |

Consumer interest in consuming local products |

Responsible consumption is developed and protected designations of origin are beginning to be recognized globally (EU). |

Promotion of local products and certifications of origin. |

|

Society |

The working conditions of workers is a much debated and socially respected issue in recent years.. |

There are gender considerations that must be taken into account in the conditions of safety and comfort. |

They propose a more equal and inclusive food production fabric, more gender balanced and empowered from the social bases. |

|

Technology |

Consumers' interest in having more information that describes the production process. |

The number of systems that allow the communication of information from the farm to the fork proliferates. |

Improve the performance of the factory exploiting the data gathered during the food processing activities |

|

Legal |

Food companies have to follow very strict food safety and other health protocols |

Conducting their operation according to health and safety regulations requires accurate information systems. |

Audits and monitoring of certifications (AENOR) allow compliance with legal requirements and give consumers confidence in the good work of a food processing company. |

|

Environment |

There is a huge impact on the environment from food production. |

Society is becoming more aware of this impact and they are willing to reduce environmental degradation. |

Companies are willing to pollute less, reducing consumption and optimising freight transport. |

|

Values |

Food fraud is an evil that has been happening in Spain with certain products, such as honey or olive oil. |

New detection and certification mechanisms have appeared, such as blockchain, or new laboratory tests. |

Explore food quality mechanisms for the prevention of fraud in products such as oil and honey. |

CRFS indicators

Study outputs of WP3 and what is planned at grant agreement: Task 3.7 – Data-driven CRFS management systems ideation:

In D3.8 there is a set of core functionalities that have been planned for the S2CP. These functionalities are described below, with a schematic image of what the interaction of S2CP and its users would be like, and finally, some examples of how stakeholders could make use of this functionality are provided. Below we highlight the functionalities that can be useful for Arganda lab, hoping that the corresponding components of the S2CP platform can be used in the scope of this lab:

Representation of real-time data for CRFS monitoring

S2CP will incorporate a system for receiving events that can be produced by sensors. Thus, it can collect information produced by sensors that may be deployed in a city or on a farm and generate information repositories for real-time visualization or monetization.

Case study: Arganda lab: The CODAN company which operates the food processing factory is currently transforming the factory from a traditional model to a Smart Factory model. CODAN is going operate the systems in order to improve the performance of the factory exploiting the data gathered in real-time during the food processing activities.

Challenge #1:

Monitoring of relevant environment parameters of food production processes. The CODAN company which operates the food processing factory is currently transforming the factory from a traditional model to a Smart Factory model. CODAN is going operate the systems in order to improve the performance of the factory exploiting the data gathered during the food processing activities.

An experiment is based on the monitoring of working conditions of workers in food production company. Gas emissions, temperature and humidity will be measured in real-time and represented in a dashboard. S2CP components will be used. A stakeholder’s workshop will be done where factory workers evaluate the feasibility of the solution.

Specific KPIs to achieve:

- KPI#1: Thermal discomfort reduction: Reduction in unitary annual number of thermal discomfort episodes in 10%.

-

KPI#2: Real-time alert notification: Generation of alerts related to real time information in less than 30 seconds since error detection.

Origin Certification and Fraud Prevention of Short Food Supply Chains

S2CP will provide a solution for optimization of multi-stakeholder dialogue processes, in which blockchain will be employed to provide some proof of concepts of monetization processes, in a reliable and transparent way. In order to ensure transparency, traceability and trust of the local food production, blockchain technology (BC) presents the natural technology fit in the so-called SFSC.

Case study: Arganda lab: It is intended to explore possibilities to incorporate into the product information, relevant data on production, such as the origin of the main foods or a carbon footprint calculation

Challenge #2:

Facilitating food transparency in supply chain: It is intended to explore possibilities to incorporate into the product information, relevant data on production, such as the origin of the main foods or a carbon footprint calculation.

A second experiment is based on the development of a marketplace, enhancing the process of dealing with providers and offering a more efficient approach in obtaining supply chain information, increasing final information associated to a product.

Specific KPIs to achieve:

- KPI#3: Improvement of user satisfaction: Improvement in users’ satisfaction and QoE (global, trustworthy and transparent information): Significant at p < 0.005

- KPI#4: Increase in availability of information on food production: Increase in availability measured by latency in access by 10%

Literature review

Here we include the results of the state of the art the researchers from UPM did regarding the scopes of the Arganda Lab:

Increase efficiency in Industry 4.0 and workers well being:

And many innovative hybrid technological mechanisms are being reported [1] every day to support and promote this revolution.

However, digitalization is not the only methodology to achieve these global objectives. Since 1970, many quality management theories, methodologies and strategies have been developed [2]. Many companies, and other institutions, have now implemented these policies, [3] which are able to guarantee the production process efficiency and workers wellbeing in the same way Industry 4.0 schemes promise. Although Industry 4.0 solutions show some qualitative and well-known advantages, such as the process automation, the remote management, or the low maintenance cost [4]; there are many barriers that prevent the Industry 4.0 paradigm adoption. Basically, the required structure from the organization, and the associated costs to the new and the traditional quality assurance solutions are totally different. While Industry 4.0 solutions are characterized by high deployment costs (investment) and sporadic technical tasks, traditional quality management policies are supported by large human resources teams and continuous human intervention (but a negligible investment is needed) [5]. Thus, any company implementing Industry 4.0 paradigm is facing a restructuration process. This is a major challenge.

- Bordel, B., & Alcarria, R. (2017). Assessment of human motivation through analysis of physiological and emotional signals in Industry 4.0 scenarios. Journal of Ambient Intelligence and Humanized Computing, 1-21.

- Koskela, L., Tezel, A., & Patel, V. (2019, July). Theory of quality management: Its origins and history. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction (pp. 1381-1390).

- Bastas, A., & Liyanage, K. (2018). Sustainable supply chain quality management: A systematic review. Journal of cleaner production, 181, 726-744.

- Bordel, B., Alcarria, R., & Robles, T. (2021). Controlling Supervised Industry 4.0 Processes through Logic Rules and Tensor Deformation Functions. Informatica, 32(2), 217-245.

- Gunasekaran, A., Subramanian, N., & Ngai, W. T. E. (2019). Quality management in the 21st century enterprises: Research pathway towards Industry 4.0. International Journal of Production Economics 2017, 125-129

Regarding the second scope that is managed within Arganda lab, which is current state of the art in food traceability solutions:

Food traceability is a multidisciplinary challenge. Some authors [1] have reported up to 13 different approaches to the problem in the research literature: from logistic management [2], to unique identification [3], transparency [4], interoperability [5] and production management [6], among others.

Some authors have studied information management techniques that can be applied in food traceability systems. Mathematical frameworks that describe the internal structure of systems and transactions [7], theoretical frameworks that determine the characteristics of the data to be collected and how they should be managed [8], or optimization algorithms [9] to identify critical paths, inefficiencies, etc. have been reported.

The legal aspects and international normative are receiving a lot of attention in the last few years [10], but the most popular approach in the last five years is Blockchain [11]. Although many different challenges related to blockchain and food traceability have been identified [12], several architectures and designs can be found applying Blockchain to international, national, or local food traceability. However, this approach is not fully compliant with European regulation, so new Blockchain networks are being designed [13]. But today, deployed food traceability systems deployed should be based on more stable technologies, with no open legal questions or challenges.

- Ringsberg, H. (2014). Perspectives on food traceability: a systematic literature review. Supply Chain Management: An International Journal.

- Cambra‐Fierro, J., & Ruiz‐Benítez, R. (2011). Notions for the successful management of the supply chain: learning with Carrefour in Spain and Carrefour in China. Supply Chain Management: An International Journal.

- Karlsen, K. M., Dreyer, B., Olsen, P., & Elvevoll, E. O. (2012). Granularity and its role in implementation of seafood traceability. Journal of Food Engineering, 112(1-2), 78-85.

- Trienekens, J. H., Wognum, P. M., Beulens, A. J., & van der Vorst, J. G. (2012). Transparency in complex dynamic food supply chains. Advanced Engineering Informatics, 26(1), 55-65.

- Ruben, R., & Zuniga, G. (2011). How standards compete: comparative impact of coffee certification schemes in Northern Nicaragua. Supply Chain Management: An International Journal.

- Carpio, C. E., & Isengildina‐Massa, O. (2009). Consumer willingness to pay for locally grown products: The case of South Carolina. Agribusiness: An International Journal, 25(3), 412-426.

- Storøy, J., Thakur, M., & Olsen, P. (2013). The TraceFood Framework–Principles and guidelines for implementing traceability in food value chains. Journal of food engineering, 115(1), 41-48.

- Karlsen, K. M., Dreyer, B., Olsen, P., & Elvevoll, E. O. (2013). Literature review: Does a common theoretical framework to implement food traceability exist?. Food control, 32(2), 409-417.

- Dabbene, F., & Gay, P. (2011). Food traceability systems: Performance evaluation and optimization. Computers and Electronics in Agriculture, 75(1), 139-146.

- Newsome, R. L., Bhatt, T., & McEntire, J. C. (2013). Proceedings of the July 2011 traceability research summit. Journal of Food Science, 78(s2), B1-B8.

- Bordel, B., Alcarria, R., & Robles, T. (2021). Denial of Chain: Evaluation and prediction of a novel cyberattack in Blockchain-supported systems. Future Generation Computer Systems, 116, 426-439.

- Galvez, J. F., Mejuto, J. C., & Simal-Gandara, J. (2018). Future challenges on the use of blockchain for food traceability analysis. TrAC Trends in Analytical Chemistry, 107, 222-232.

-

Robles, T., Bordel, B., Alcarria, R., & Sánchez-de-Rivera, D. (2020). Enabling trustworthy personal data protection in eHealth and well-being services through privacy-by-design. International Journal of Distributed Sensor Networks, 16(5), 1550147720912110.

Technical challenge

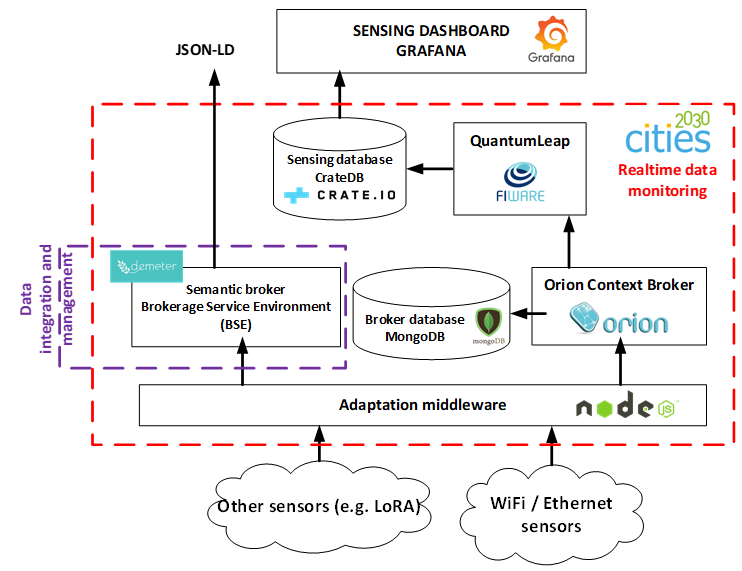

To do this, a technological environment will be designed that allows us to obtain real-time information on the environmental conditions of a factory and that, in turn, allows us to capture relevant events belonging to the distribution chain of a product. Such as the temperature at which it is transported, the location of the different links in the chain, or the guarantee of origin. This system is designed with the help of WP6, as a component of the S2CP platform: Real-time information. Below is a visualization of this challenge where you can see the relationship and data exchange between different subsystems:

As we can see, different types of sensors can supply data to real-time data monitoring, such as WiFi/Ethernet sensors, and other sensors that communicate with well-stablished technologies such as LoRA or SigFox. A connector-based adaptation middleware serves as a communication proxy and transmits information to two types of brokers:

- The semantic broker BSE publishes the interfaces for data consumption through a semantic model compatible with the data integration and management tool, and based on semantic models from previous projects such as DEMETER.

- The Orion Context Broker is a FI-WARE component optimized for sensor data communication, which supports the NGSIv2 protocol.

To provide persistence to the information received by the sensor infrastructure, the QuantumLeap module is used, another FI-WARE component that saves all sensor updates in a CrateDB sensing database.

Finally, this database can be used as a source of information for the representation of the information received in a dashboard, for subsequent analysis, filtering and as a decision support system.

Data collection and data analysis

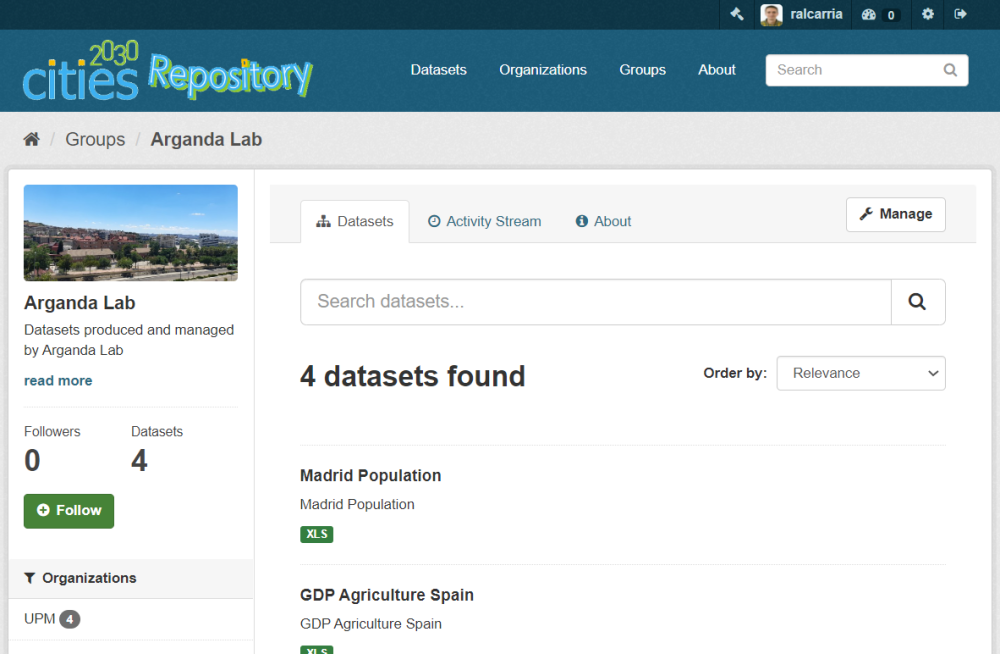

Arganda Labs is totally connected to the technological framework provided in Cities2030 via WP6. Below, we can see how Arganda’s data is provided to various S2CP components:

Communities platform:

Arganda Lab has been created in Cities2030 Communities:

https://cities2030-community.gisai.eu/labs/page/5-welcome-page/

The second component in with Lab managers have been working is the S2CP dashboard:

The dashboard is published in: https://cities2030.primelayer.pt/

Currently there is no information available regarding Arganda Lab, but Lab team is working with Primelayer for designing the best possible visualisation.

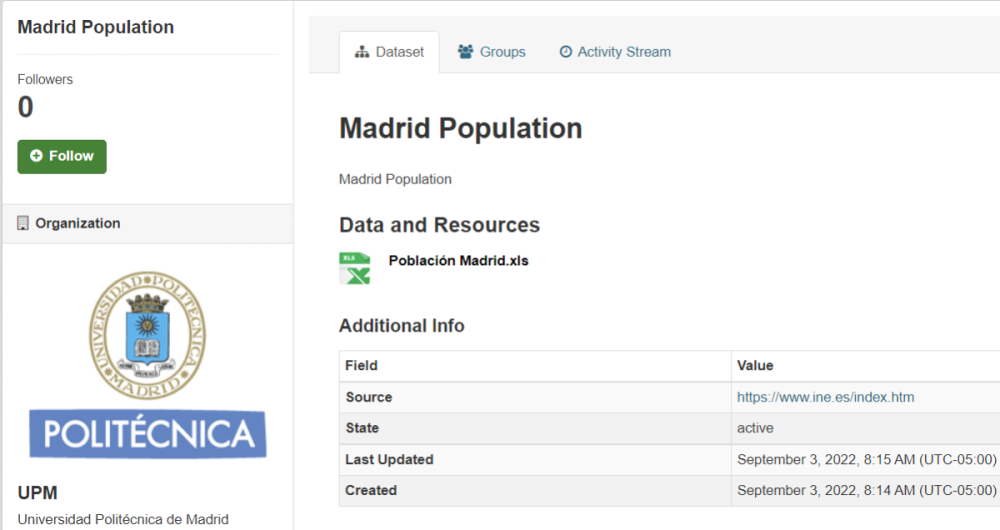

The third component is the data repository.

The repository is here: http://cities2030-repository.gisai.eu/

In this repository we uploaded 4 datasets, related to statistical data from the country and the autonomous community of Madrid, in which Arganda is placed.

Here we can see a preview of the data that can be downloaded

Results of innovation experiments will be published in these S2CP components.